The development of industry and the latest technologies are inextricably linked. Also in the field of inventory of production plants. We have laser scanners of various specifications. Thanks to that, we are always able to choose the equipment appropriate to the client’s expectations. We can offer sub-millimeter precision and unrivaled speed.

The laser scanning technology enables quick and complete documentation of hard-to-reach spaces in a safe manner. The most common form of its use are inventory measurements of industrial machines or transmission networks on the premises of the plant. We have many years of experience in both of these areas. So far, we have measured machines during the technical break so that production does not have to be stopped for the duration of the measurement. We also made an inventory of fire protection installations in large production plants. Did we finally use our scanners in places where direct measurement by a human was impossible due to human safety?

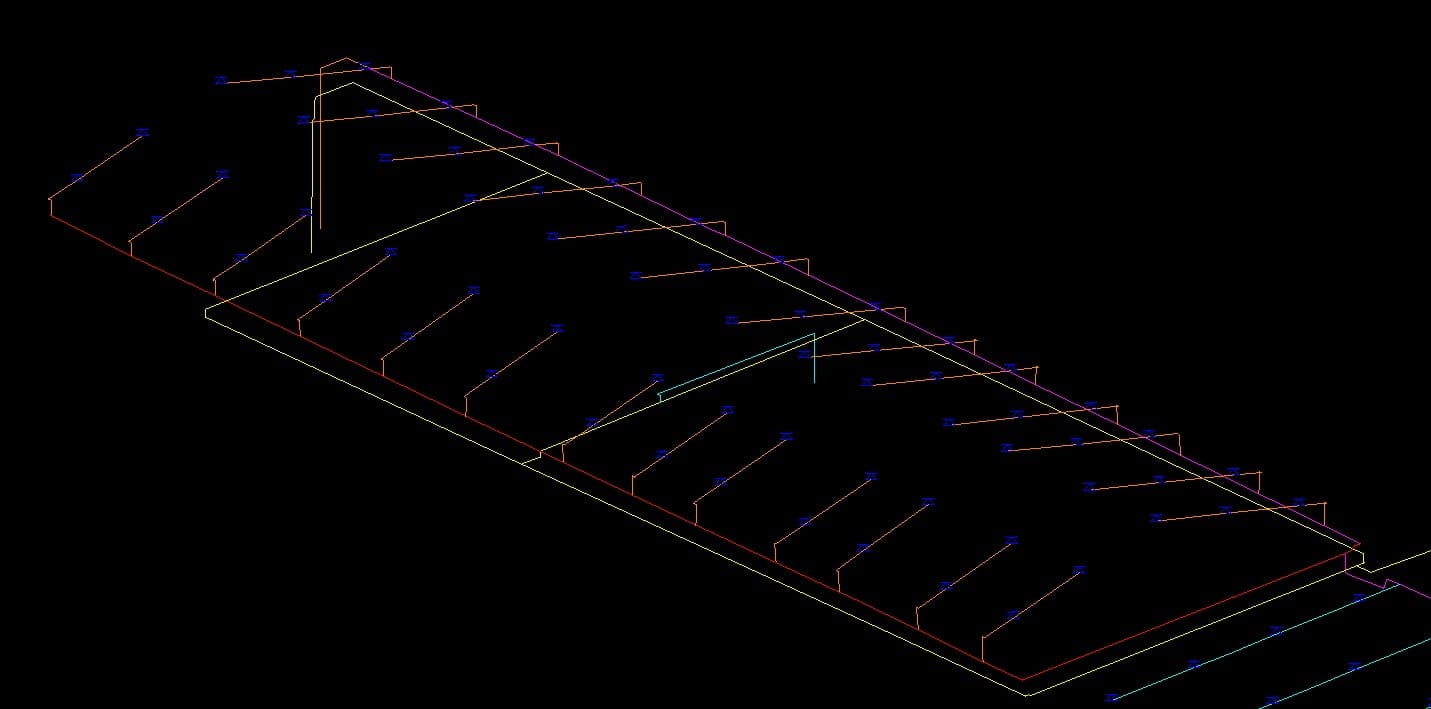

Another form of using laser scanning are all processes in the field of machine engineering. Precise measurement makes it possible to restore worn-out elements, or to improve them through modernization. The cloud of points from terrestrial laser scanning makes it possible to send a complete image of machine elements at a distance, e.g. to the manufacturer of machine components. This practice saves a lot of time and money. Depending on the client’s needs, the product we provide can be a point cloud, MESH model, object model, or 2D CAD or 3D CAD drawing.